Brake Pad Myths and Mistakes

If you sit behind an auto parts counter or read online automotive forums, you might run across some myths and bad advice about brake pads. Most of these opinions are false and they can even be dangerous. Below are the top 10 brake pad myths or opinions you might encounter and why they are wrong.

“I don’t drive fast, I only need the cheapest brake pad.”

FALSE! You always need the full performance of the brake pad during a panic stop. A panic stop can occur at 25 or 75 mph, no matter the speed you need to stop. Road hazards and bad drivers do not discriminate on the price of your brake pads.

“By the time the friction material wears out, corrosion will not be an issue.”

FALSE! It is impossible to predict how many miles a brake pad will last on any vehicle due to different driving habits and commutes. But, what is even more difficult to predict is the length of time a brake pad will be on a car or truck.

The longer a brake pad is on the road, the longer it is exposed to moisture and corrosive elements like road salt. Rust never sleeps and can happen even when the brakes are not moving.

Low-quality brake pads use basic corrosion prevention methods like paint, high-quality brake pads with advance methods of corrosion prevention like galvanization.

Often, brake pads are replaced because corrosion has caused uneven brake pad wear and delamination of the friction material on the inboard brake pads. The outboard brake pads might have plenty of material. This means that the driver did not get the full value out of the set of brake pads. Using a premium brake set with advanced corrosion protection like galvanization will prevent this from happening.

“All replacement brake pads are the same.”

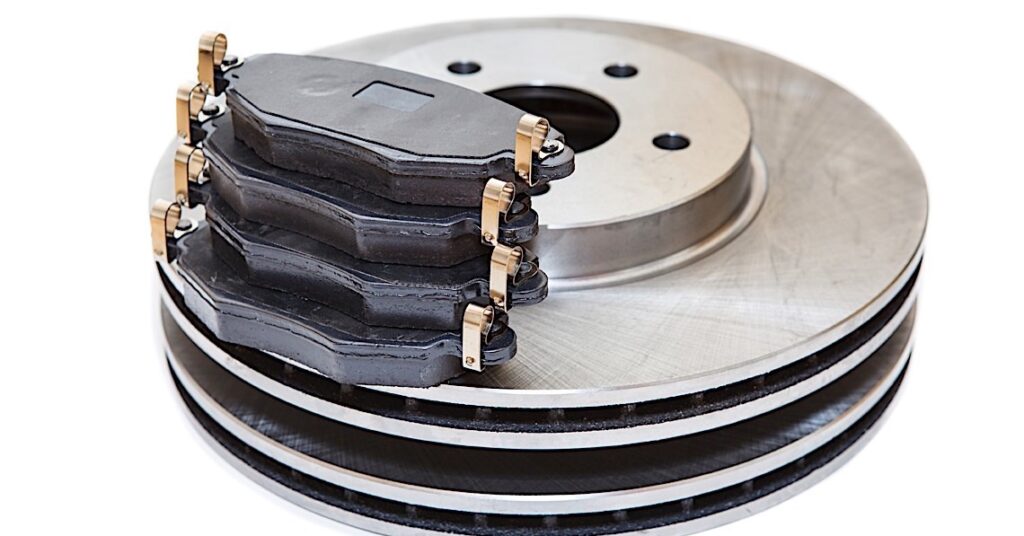

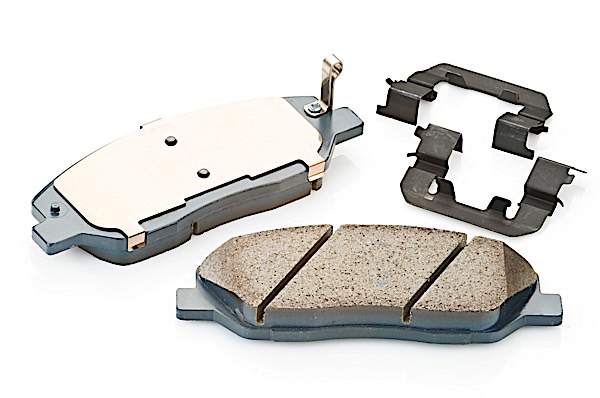

FALSE! The overall shape of the brake pad will be the same for a given application across all brands and manufacturers, but it does not mean they will all perform the same. If you want to see how brake pads are different, look at the metal backing plate and not the friction material.

Manufacturers can use various grades of steel, stamping processes and friction attachment methods. Also, manufacturers can use different types of corrosion protection for the backing plate. Subtle clues in the backing plate will tell you the quality of the brake pad set.

A low-quality backing plate will use steel that already has iron oxides inclusions (precursor to corrosion) embedded in the surface. When the backing plate is stamped, the dies might be worn out. This will cause the backing plate to have a tight fit in the caliper bracket. When it comes time to protect the pad against corrosion, the low-quality manufacturer will use a solvent-based paint that can’t withstand the environment in the wheel well the vehicle. Take a sniff, and if it smells like paint, it is probably painted.

A high-quality brake pad will use a better grade of steel that is less likely to corrode. When stamping the backing plate, the manufacturer may use several steps to ensure the backing plates are the correct dimensions for the caliper bracket. Also, during the stamping process they can include extra steps to apply hook or other elements to mechanically attach the friction material. When it comes to time to prevent corrosion, a high-quality brake pad will use a process like galvanization that will give the backing plate a silver finish.

Galvanizing leaves behind a durable coating that encapsulates the entire backing plate, including the bonding area for the friction material. Galvanization can prevent corrosion from getting between the backing plate and friction material and cause rust jacking.

While friction materials and formulations get all of the attention, the backing plate is the foundation of the brake pad and the distinguishing factor between different brands and grades of quality.

“ABS and stability control systems are not affected by replacement brake pad performance.”

FALSE! Anti-lock brakes and stability control systems are very sophisticated with pumps, electronic solenoids and many sensors. But, these advanced safety systems use the brake pads to make corrections to the dynamics of the vehicle. If the replacement brake pads don’t match the performance of the original brake pads, it could cause the ABS and stability control system to make more correction and it might take more distance and time to bring the vehicle under control.

“I am selling the car soon. I don’t need an expensive brake pad.”

FALSE! If you want to scare away potential buyers, brake noise during the test drive will do the trick! Low-quality brake pads are cheap because the manufacturer might use brake shim held on with adhesive. These shims can’t isolate noise like a fully floating shim held on with clips. Also, a cheap set of pads might not include hardware with replacement abutment clips for the caliper bracket.

If a brake pad manufacturer wants to make a cheap set of pads, they will skimp on engineering and testing. Some companies will use a friction formulation not designed for the vehicle. This can cause changes to pedal feel and even increase the occurrences of noise.

Putting the least expensive brake pad on a vehicle could create safety problems for the new owner. The performance or the replacement brakes will not be measured in dollars and cents, but rather in inches and feet.

“The only difference between a premium brake pad and an economy brake pad is the warranty.”

FALSE! If you are buying the brake pad for only the warranty, you need to do more research. Most brake pad warranties cover only defects. Premium brake pads are more expensive because they use better materials, engineering and manufacturing processes.

“I don’t need brake pads that come with hardware, the original hardware looks like new.”

FALSE! The appearance of the hardware will not show if it is past it’s prime. OEMs will use stainless steel for the abutment and anti-rattle clips , and they will never corrode. But, the steel could be fatigued. Heating and cooling cycles that happen when the brakes are applied weaken springs and anti-rattle clips. Weak hardware parts can result in excessive caliper/pad movement or binding. This will typically cause noise when the brakes are applied.

“I can trust every brake pad I can buy because the government regulates stuff like that.”

FALSE! Everybody wants safe brakes, right? You want the assurance that any brake linings you are installing will provide adequate braking and meet all applicable safety standards. But guess what? There are no federal safety standards for replacement brake linings.

Given the fact that aftermarket brake linings are essentially unregulated, how can you be sure the brake pads you are installing on meet any standards? The best advice here is to buy name-brand products from suppliers who stand behind their products. Do your research!

“I can handle the bad brakes on my car until payday.”

FALSE! If you are experiencing a low brake pedal, grinding brakes or any changes in the performance, go to a shop and have the brakes serviced. An accident does not wait for payday.

If I get in a wreck, I can blame the brakes!

False! Claiming that your mistake was the fault of the vehicle’s brakes won’t hold up in some courts. They will hold you accountable for the condition of your brakes.