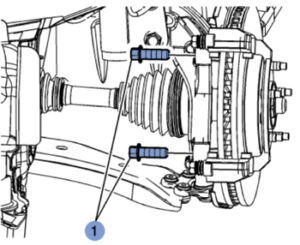

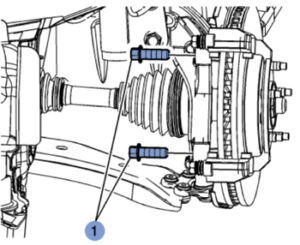

On most new GM vehicles, in order to reinstall the caliper bracket you have to have a torque angle gauge and two new caliper bracket bolts. The bolts are Torque-to-Yield (TTY) fasteners that stretch. TTY fasteners are mounting fasteners which are torqued beyond the state of elasticity and therefore undergo plastic transformation, causing them to become permanently elongated.

On most new GM vehicles, in order to reinstall the caliper bracket you have to have a torque angle gauge and two new caliper bracket bolts. The bolts are Torque-to-Yield (TTY) fasteners that stretch. TTY fasteners are mounting fasteners which are torqued beyond the state of elasticity and therefore undergo plastic transformation, causing them to become permanently elongated.The wheel bearing hub units also use TTY bolts to hold the unit to the knuckle. If you do not use the correct procedure or reuse the old bolts, the fasteners could fail.

On the Buick Regal for example, you need to tighten to 150 Nm (111 lb ft) and turn the bolt 45 degrees and then another 15 degrees. Rear caliper should be tightened to 100 Nm (74 lb ft) and turn the bolt 60 degrees.

In the engine world, TTY fasteners allowed for smaller fasteners while improving clamping loads. It took engine builders a while to recognize these types of fasteners. For tech servicing brakes the stakes are a lot higher.

One thought on “BRAKE TECH: Torque-to-Yield Caliper Bracket Bolts on GM Vehicles”

Comments are closed.