Have ever had a brake pad that felt like it was extremely tight squeeze or loose when installed in the caliper bracket? The problem may not be your preparation of the caliper bracket or the new hardware. The problem might be the pad’s backing plate.

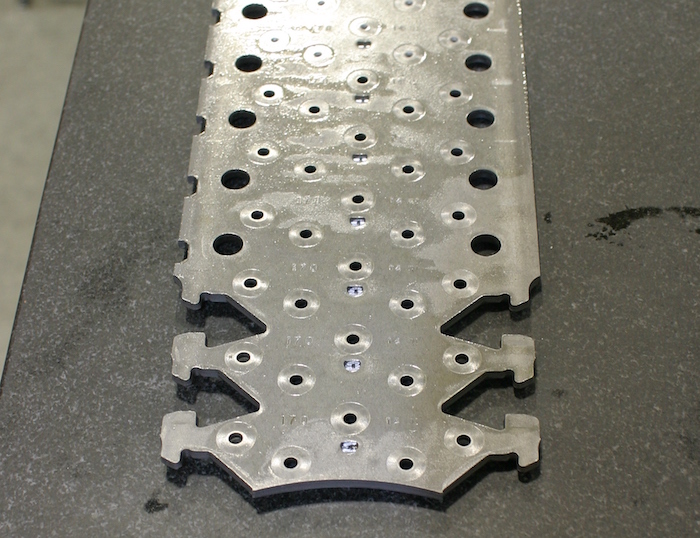

Most brake pad backing plates are stamped out of steel. The force required to stamp the plate is huge and getting a fine edge on the ears of the pads can be difficult due to the deformation of the steel and dies in the press.

Material from the top of the backing plate can “roll-over” on to the sides of the plate. It gets even worse if the stamper has used the tooling a little too long. This may result in the ears of the pads to not be the correct size. Also, a manufacturer may go with a thinner gauge of metal for the backing plate.

You could grind the ears of the pad to fit the caliper. But it is difficult to impossible to create a proper surface with an angle or bench grinder. Also, you could be removing coatings and plating designed to resist corrosion. This can result in a noise comeback. Your best option is to send the pads back for another set.

Premium pads start with premium backing plates. The plate needs to stiff and resist bending under load. Weak backing plates can cause noise and a soft pedal. Also, premium backing plates use better tooling so less metal is rolled over onto the edges.

From this video, it is easy to see backing plates are just as important as the friction material.