I recently bought an Olloclip for my iphone. It has a great marco lens for zooming in on small details. It gave me a chance to look at some brake pads I recently took off a truck. It is amazing how bad some brake pads can look up close and how a cheap pad can fail prematurely and cause noise.

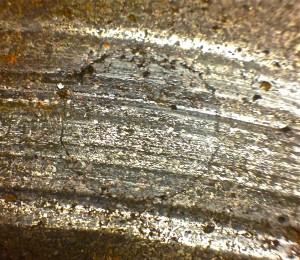

What is this? A crop circle? No, it is fracturing of friction material around a molding hole in the backing plate. This can happen on some pads for two reasons. First, different rates of thermal expansion over many heat cycles can cause the material to crack. Second, the backing plate might be too thin or poorly engineered and flexes too much and causing the friction material to crack.

Over time, a puck of friction material can even come loose. Not only can this hurt braking performance, it can cause noise and even more friction material to come off the face of the pad.

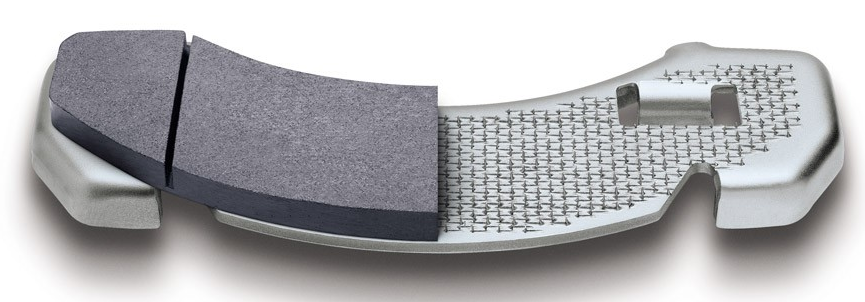

The holes in the backing plate are for integral molding where the friction material flow through the holes to bond the friction material to the backing plate. This method replaced rivits for some applications.

Keeping friction material attached to a backing plate is a tricky piece of engineering. The friction material has to endure mechanical forces and an environment that is highly corrosive. If the bonds between the friction material are weak, water, road salt and de-icing brines can work their way between the components. This can cause the friction material to separate from the backing plate. This hurts braking performance and causes noise.