With the first phase of the Environmental Protection Agency’s (EPA) Copper-Free Brake Initiative coming to a close at the end of the year, Bendix Commercial Vehicle Systems LLC reminds fleets and owner-operators to make sure they’re keeping up with the necessary changes in aftermarket air disc brake (ADB) friction formulation.

“It’s important that fleets, distributors, and everyone who does brake pad changes is aware of what’s going on with various Bendix replacement pads and labeling,” said Keith McComsey, Bendix director of Air Disc Brake and Systems. “And with the significant increase in ADB adoption over the past decade, there’s a particular interest in ADB pad changes.”

The Initiative

In January 2015, organizations within the automotive and commercial vehicle industries – including trucking – signed onto the Copper-Free Brake Initiative, along with the EPA and the Environmental Council of the States. This action was taken because copper from stormwater runoff can be harmful to the environment, affecting plants and animals – and when used in brake pads, it makes its way into the air and water through the fine dust released from friction during braking.

In 2010, according to EPA estimates, vehicular braking in California alone released 1.3 million pounds of copper into the environment. That year, both California and Washington passed laws reducing the amount of copper permitted in brake pads.

Phase 2

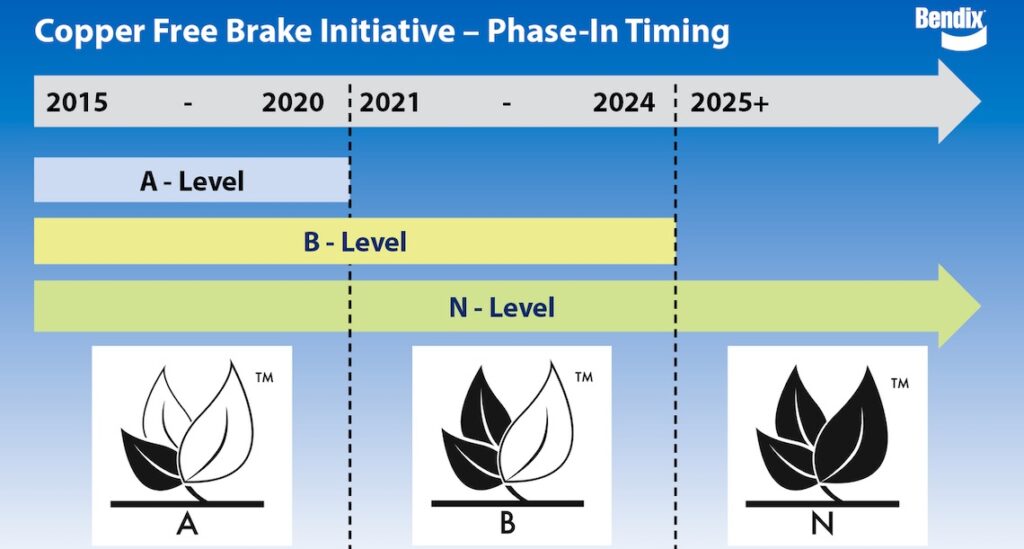

B-Level compliance, or phase 2, of the initiative takes effect on Jan. 1, 2021, and limits the amount of copper to no more than 5% by weight. Other material limits remain unchanged. In January 2025, copper’s limit will drop to 0.5% – one-half of 1% – by weight for N-Level compliance. The agreement also commits participants to take steps to educate the automotive and trucking industries on the changes and provides guidelines for marking and labeling friction material packaging and products.

“Even though many Bendix friction materials have been compliant with the 2021 standards for a long time, some older aftermarket ADB pads will be phasing out of compliance at the end of the year,” McComsey said. “For customers currently using these, we’ve been including postcards with the replacement kits letting them know about the change and pointing them to the compliant friction.”

Bendix Compliant Brakes

The A-Level-compliant frictions, which include both the Bendix BX275 OE-level friction and the aftermarket BA235, will become obsolete. The suitable B-Level copper-compliant replacements are the Bendix BX276 and BX283 pads, which are OE-level pads already available in the North American market. Both will remain compliant through 2024, while providing longer friction life and meeting FMVSS-121 stopping distance and park hold requirements. Bendix will also launch the BA236 pad in 2021, an aftermarket friction that will be B-Level copper-compliant through 2024.

Bendix parts and replacement kit numbers involved are:

• BX275 – obsolete Dec. 31, 2020

• BA235 – obsolete Dec. 31, 2020

• BX276 – available; compliant through 2024

• BX283 – available; compliant through 2024

• BA236 – coming in 2021; compliant through 2024

Bendix wheel-end solutions include air disc and drum brake systems, automatic slack adjusters, spring brakes, friction, and remanufactured brake shoes that provide lower total cost of ownership while delivering on safety, stopping power, and reliability. Bendix helps fleets and drivers in the areas most critical to their success by improving vehicle performance and efficiency, and by backing its products with unparalleled post-sales support. By strengthening return on investment in the technologies that improve vehicle and driver safety, Bendix supports safer North American roads for all who share them.

“When Phase 3 of the initiative rolls around on Jan. 1, 2025, Bendix will be ready for that too,” McComsey said. “We’re already engineering copper-compliant ADB friction for the most stringent level, with plans for production to begin well in advance of the deadline.”