This pad comes courtesy of Reddit’s Just Rolled into the Shop.

This pad comes courtesy of Reddit’s Just Rolled into the Shop.

The pad has been worn well past recommended specifications. By looking at the wear sensor, it must have been screaming like a stuck pig. The driver was able to catch it before the backing plate contacted the rotor.

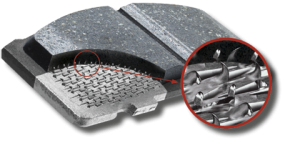

The hole in the backing plate is where the manufacturer flowed the friction material through the backing plate to create a better bond. This is called integral molding. But, the holes can cause material separation and flexing in the backing plate. The result of which is the puck of friction material in his hand.

A better solution is mechanical attachement like NUCAP’s NRS system. NRS hooks are engineered to grab the friction material and prevent the friction material separating from the backing plate. Also, NRS can eliminate the holes in the backing plate that cause flex and fracturing of the brake pad.

A better solution is mechanical attachement like NUCAP’s NRS system. NRS hooks are engineered to grab the friction material and prevent the friction material separating from the backing plate. Also, NRS can eliminate the holes in the backing plate that cause flex and fracturing of the brake pad.