Ratchet and Wrench interviewed Scott Lambert of the Global Brake Safety Council (GBSC) on brake pad regulations and the differences between some OE and aftermarket brake pads. A great interview that will build awareness with shop owners.

What You Need to Know About Brake Pad Regulations

What You Need to Know About Brake Pad Regulations

Lambert is one of the founding members of GBSC, a non-profit made up of individuals in the brake industry, with the common goal of making brake safety paramount, by educating the general public as well as installers and those within the automotive industry.

Most individuals outside of the industry, and a good number within, are under the assumption that aftermarket brake pads have all of the same safety and quality requirements that OE brake pads have, Lambert says. Unfortunately, that is not always the case.

The government bodies in both the U.S and Canada have strong regulations for OE parts, they have to go through a series of testing that aftermarket parts do not.

Ratchet+Wrench sat down with Lambert to discuss more how this affects the repair industry, what shop owners should look out for and how the GBSC works with the government to try and change the regulations.

Why is this something repair shop owners should be aware of?

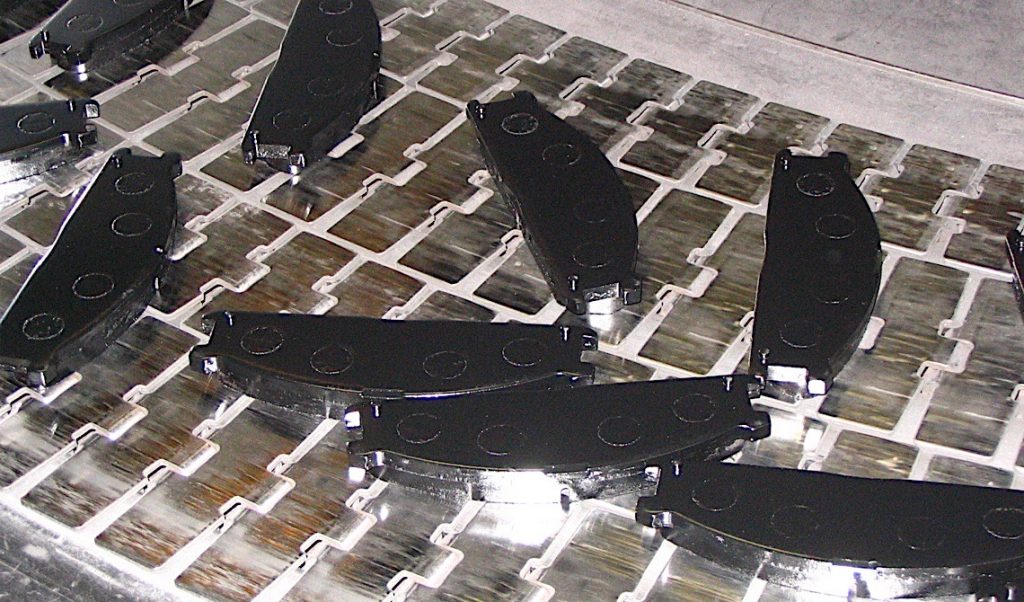

Firstly, it’s important to note that not all aftermarket brakes are poor quality. There are aftermarket companies that do a great job and consider safety to be paramount, but those companies are getting beat right now because of a lot of offshore offerings. Companies are manufacturing their brake pads and parts overseas from places with low safety standards and subpar materials. As a result, that trickles down to the people who are buying it, including repair shops.

There’s a Frost & Sullivan study that was done back in 2014…

–